Schluter®-DITRA-HEAT-E-HK

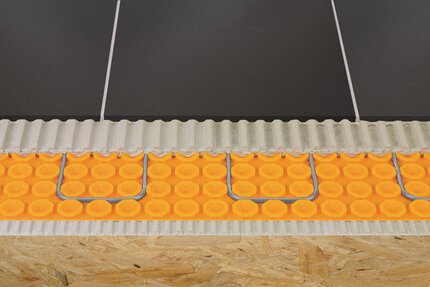

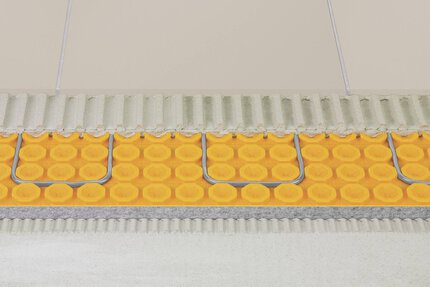

Electric radiant floor heating cables used with DITRA-HEAT membrane

- Cables snap into the membrane; clips and fasteners are not required

- No self-levelers required to encapsulate the cables; installation time significantly reduced

- No return to thermostat required

- Produces virtually zero electromagnetic fields

- 120 V and 240 V options available in a variety of lengths

- Provides electric floor warming for use beneath tile, stone, or other resilient floor coverings (e.g. LVT)

- Note: Two floor temperature sensors are provided with the heating cables. These can be installed at the same time as the cable.

Find recommended accessories here

IMPORTANT Ordering Information for Schluter®-DITRA-HEAT Cables

- Do not purchase a heating cable that is the same size as the area to be tiled; you will be left with too much heating cable!

- Very important: Never CUT or modify the heating cable in any way. This would change the cable resistance, will cause damage to the cable, and could cause cable overheating.

- A cable spacing of 3 studs is standard.

- Cable may also be spaced at continuously alternating 3 stud – 2 stud intervals in isolated areas or over the entire floor. This practice may be desirable to increase heat output (e.g., over uninsulated on or below grade concrete subfloors) or to consume more cable length in a given area (e.g., when using the standard 3 stud spacing doesn’t allow the selected cable to fit the floor area and respect minimum spacing requirements from walls, partitions, etc.)

- A cable spacing of 4 studs is not recommended, as it can produce inconsistent floor surface temperatures.

- Minimum spacing from walls, partitions, and fixed cabinets is 2" (50 mm).

- Minimum spacing from other heat sources (baseboard heaters, other fixed heating devices, fireplaces, etc.) is 8" (200 mm).

- Minimum spacing from any plumbing drain and forced air heating duct is 4" (100 mm).

- Minimum spacing from centerline of toilet drains is 7" (180 mm).

- NEVER install the heating cable under vanities with no air space beneath, bathtub platforms, free standing bathtubs with no air space beneath, kitchen cabinets and islands, any other fixtures in storage or clothing closets. Excessive heat will build up in these confined spaces and may cause cable overheating.

- NEVER install the heating cable under or through a wall, partition, or through a floor.

- NEVER install the factory splice (i.e., black plastic junction between the cold lead and gray heating cable) in the wall. This will cause overheating, system failure, and could cause damage. This splice must be installed entirely under the floor covering, as shown in the heating cable installation instructions.

- It is helpful to plan the location of a buffer zone, as it is not always possible to predict where the heating cable will end. The buffer zone is an area where heating is not essential, typically behind a toilet or adjacent to a door opening. This area allows for placement of excess heating cable. Heating cables may also be installed 6" (150 mm) from the wall to create a buffer zone.

- Heating cable testing is required while the heating cable is on the spool and at two subsequent steps during installation to ensure cable quality and for warranty purposes. A megohmmeter is required for the insulation resistance testing of the heating cables. Insulation resistance testing is strongly recommended.

- Consult a qualified electrician before ordering DITRA-HEAT heating cables to ensure you order the correct voltage for your installation.

DITRA-HEAT Estimator

Estimate your membrane and cable requirements without breaking a sweat.

Schluter®-DITRA-HEAT-E-HK are twisted pair heating cables designed for integration with the DITRA-HEAT uncoupling membrane in interior floor warming applications.

All substrates must be clean, even, and load bearing. Bond inhibiting surfaces must be removed prior to the application of DITRA-HEAT. For complete installation guidelines and warranty criteria, please refer to the downloadable Schluter®-DITRA-HEAT Installation Handbook or to the installation video online.

Note: Type, thickness, and format of the tile or stone surface covering must be suitable for the intended application. Minimum tile format is 2" x 2" (5 cm x 5 cm).

Applications with tile formats less than 2” x 2” (5 cm x 5 cm) require special considerations, please contact Schluter-Systems Technical Services Representatives at 800-472-4588 (USA) or 800-667-8746 (Canada) for more information regarding installation requirements and warranty eligibility.

Alternate Floor Coverings over DITRA-HEAT

Please refer to detail DH-AFC (see the Alternate Floor Coverings over DITRA-HEAT Technical Bulletin available for download below,) and the Schluter®-DITRA-HEAT Installation Handbook for complete installation guidelines.

Use our DITRA-HEAT calculator to find out what products you need to complete your specific installation.

FAQ

What is the minimum stud spacing when installing the Schluter®-DITRA-HEAT-E-HK heating cables?

A cable spacing of 3 studs between runs is standard. However, cable may also be spaced at continuously alternating 3 stud – 2 stud intervals in isolated...

Read moreCan Schluter®-DITRA-HEAT-E-HK heating cables be installed on a shower bench?

Yes, DITRA-HEAT-E-HK heating cables can be installed on the top surface of shower benches. Care must be taken to install...

Read moreCan other manufacturer’s heating cables be installed with Schluter®-DITRA-HEAT membrane?

The DITRA-HEAT-E-HK heating cables are specifically designed to integrate with the DITRA-HEAT membrane...

Read moreWhy is megohmmeter testing strongly recommended for Schluter®-DITRA-HEAT-E-HK heating cables?

The insulation resistance test is intended to detect very small breaks throughout the cable insulation before, during, and after installation...

Read moreWhere can I find a megohmmeter to perform the insulation resistance test?

Megohmmeters may be found at local electrical supply wholesalers or online retailers such as Grainger, Mouser Electronics, Amazon, etc...

Read moreMy megohmmeter is reading OL or I; is this a good reading for the heating cable insulation resistance test?

If your megohmmeter is reading "OL" (over load) or "I" (infinity), these are commonly used readings on megohmmeters...

Read moreHow do I connect the Schluter®-DITRA-HEAT-E-HK Heating Cables to a Schluter®-DITRA-HEAT-E-RSD thermostat?

For instructions on connecting the DITRA-HEAT-E-RSD thermostat, please reference the Schluter®-DITRA-HEAT Thermostat User’s Guides or...

Read moreI ran out of room for my heating cables, can I cut them or put them under my cabinets?

NEVER cut or modify the heating cable in any way. This would change the cable resistance, will cause damage to the cable, and could cause cable overheating...

Read moreHow do I select the correct length Schluter®-DITRA-HEAT-E-HK heating cable for my floor warming project?

The Schluter®-DITRA-HEAT membrane is selected according to the size of the area to be tiled. The DITRA-HEAT-E-HK heating cable is selected...

Read moreCan Schluter®-DITRA-HEAT-E-HK heating cables be installed on walls?

What are the restrictions on where I can install the Schluter®-DITRA-HEAT heating cables?

The DITRA-HEAT heating cables cannot be installed under vanities with no air space beneath, bathtub platforms...

Read moreCan more than one DITRA-HEAT-E-HK heating cable be connected to the Schluter®-DITRA-HEAT-E Thermostats ?

Multiple DITRA-HEAT-E-HK heating cables can be connected and controlled by a single DITRA-HEAT-E thermostat, if the total current is less than 15 amps...

Read moreHow do I choose between the 120V and a 240V Schluter®-DITRA-HEAT-E-HK heating cables?

There is no single determining factor. In general, 120V heating cables must be connected to 120V power sources...

Read moreEvaluations and Listings

Schluter®-DITRA-HEAT-E-HK Heating Cables are certified by CSA to CAN/CSA-C22.2 No. 130-16 (Canada)

Schluter®-DITRA-HEAT-E-HK Heating Cables are certified by CSA to UL 1673 (US)

Schluter®-DITRA-HEAT-E-HK Heating Cables are listed by UL to UL 1683 (US) and CAN/CSA-C22.2 No. 130-16 (Canada)

Watch & Learn

About the product

Schluter®-DITRA-HEAT: Cables and Temperature Sensor Installation

How to install DITRA-HEAT electric floor warming in a shower

Mike Holmes on Schluter®-DITRA-HEAT

Find some existing tutorials and project documentation videos to learn how-to get the best out of our products - for more fun in your life, start now!

Watch more videos / playlists