Schluter®-DITRA-HEAT-DUO-PS

Peel & stick uncoupling membrane with sound control and thermal break

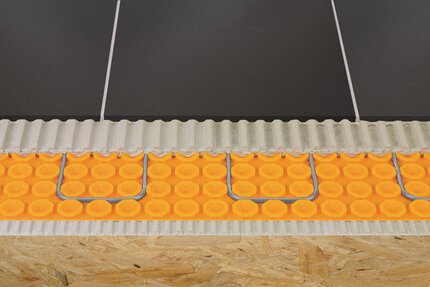

- Simply remove the transparent release film from the fleece side of the membrane to expose the layer of adhesive, and embed into substrate

- No thin-set required to install membrane means a faster and easier installation

- The membrane can easily be repositioned until pressure is exerted

- Features sound control and thermal break

- Reduces impact sound transmission through floor-ceiling assemblies, making it ideal for multi-story construction

- Reduces heat loss to the substrate when installed over concrete

- Less mess, less cleanup, and fewer tools required

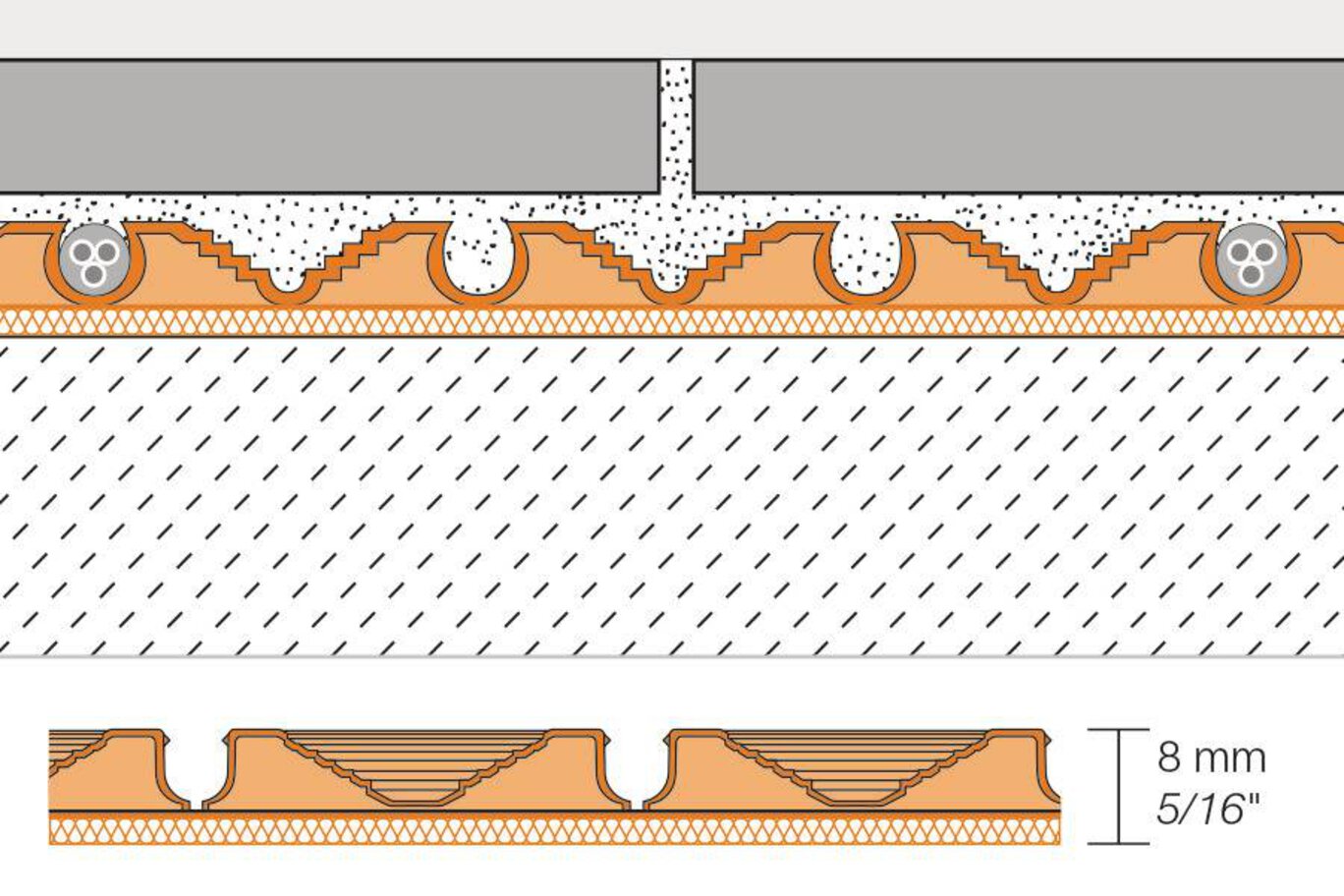

- Nominal 5/16” (8 mm) thickness minimizes tile assembly thickness and reduces transitions to lower surface coverings

- Self-leveling compounds are not required to encapsulate the cables into the membranes

- Available by the roll or by the sheet to accommodate various room sizes

- If application area requires a membrane that meets or exceeds requirements of ANSI A118.10, please refer to thin-set versions of DITRA-HEAT and DITRA-HEAT-DUO. Alternatively, the DITRA-HEAT-PS or DITRA-HEAT-DUO-PS membranes may be covered with the Schluter®-KERDI membrane, which is certified to meet ANSI A118.10.

Find recommended accessories here

DITRA-HEAT Estimator

Estimate your membrane and cable requirements without breaking a sweat.

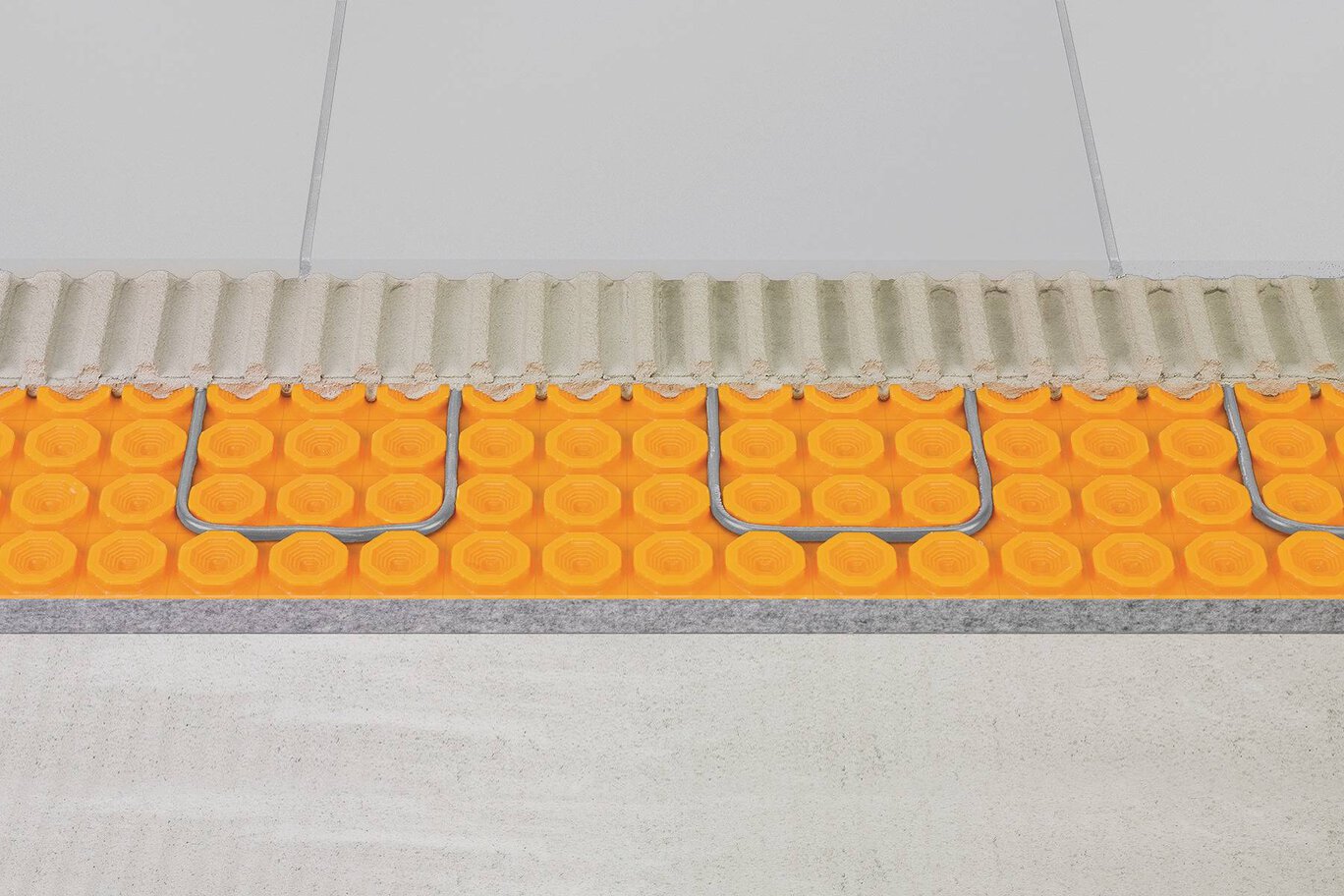

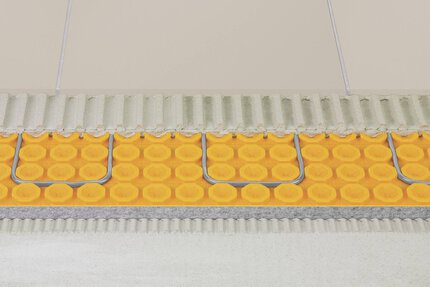

DITRA-HEAT-DUO-PS peel and stick membrane features a pressure-sensitive adhesive (PSA) to bond the membrane to the substrate, replacing the need for thin-set mortar. The peel and stick versions integrate customizable, comfortable electric floor warming with the same core functions of DITRA-HEAT: uncoupling, waterproofing, vapor management, and support to ensure a long-lasting installation. DITRA-HEAT-DUO-PS features an integrated thermal break to reduce impact sound transmission through floor-ceiling assemblies, reduce heat loss to the substrate, and improve floor warming response time.

Floor Warming

DITRA-HEAT-DUO-PS combines the flexibility of loose heating cables with the ease of installation of mat systems. Cables can be placed wherever heat is desired, without creating height differences in the floor. Self-leveling compounds are not required to encapsulate the cables for ceramic, porcelain, and stone tiles, significantly reducing installation time and effort compared to uncoupling membranes over other electric floor warming systems. Self-leveling compounds are approved for use only when installing alternative floor coverings over the DITRA-HEAT membranes.

Uncoupling

Tile has been successfully installed for thousands of years by incorporating an uncoupling layer, or forgiving shear interface, within the tile assembly. DITRA-HEAT-DUO-PS provides uncoupling through its geometric configuration, which allows for in-plane movement that effectively neutralizes the differential movement stresses between the substrate and the tile, thus eliminating the major cause of cracking and delaminating of the tiled surface.

Waterproofing

DITRA-HEAT-DUO-PS provides reliable waterproofing. Its polypropylene composition protects the substrate from moisture penetration, which is particularly important in today’s building environment where most substrates are moisture-sensitive.

The Schluter®-DITRA-HEAT-DUO-PS membrane does not comply with the requirements specified in ANSI A118.10 – American National Standard Specifications for Load Bearing, Bonded, Waterproof Membranes for Thin-set Ceramic Tile and Dimension Stone Installation. For applications requiring membrane compliance with or certification to the ANSI A118.10, select the DITRA-HEAT-DUO membrane that is installed with thin-set mortar. Alternatively, the DITRA-HEAT-DUO-PS membrane may be covered with the Schluter(R)-KERDI membrane, which is certified to meet ANSI A118.10.

Vapor Management

The free space on the underside of DITRA-HEAT-DUO-PS provides a route for excess moisture and vapor to escape from the substrate that could otherwise cause damage to the tile covering above. Thus, DITRA-HEAT-DUO-PS effectively manages moisture beneath the tile covering.

Support/load distribution

When placed on a solid foundation, columns or pillars can support tremendous loads. The same physical principle applies to DITRA-HEAT-DUO-PS installations. Column-like mortar structures are formed in and between the studs on the surface of the matting. Loads are transferred from the tile covering through these column-like mortar structures to the substrate. Since DITRA-HEAT-DUO-PS is virtually incompressible within the tile assembly, the advantages of uncoupling are achieved without sacrificing point load distribution capabilities.

Alternate Floor Coverings over DITRA-HEAT-DUO-PS

DITRA-HEAT-DUO-PS is suitable for applications with engineered wood, vinyl, wood plastic composite (WPC), luxury vinyl tiles (LVT), luxury vinyl planks (LVP), stone plastic composite (SPC) tiles and planks, and laminate flooring. See the Alternate Floor Coverings over DITRA-HEAT Technical Bulletin for more information, including requirements and limitations.

Storage: Store the DITRA-HEAT-PS and DITRA-HEAT-DUO-PS membrane in a frost-free environment 41 - 85°F (5 - 30°C). If exposed to extreme conditions, acclimatize to ambient temperature 24 hours prior to installation. The membranes are not UV stable and must be stored out of direct sunlight.

All substrates must be clean, even, and load bearing. Bond inhibiting surfaces must be removed prior to the application of DITRA-HEAT-DUO-PS. For complete installation guidelines and warranty criteria, please refer to the downloadable Schluter®-DITRA-HEAT Installation Handbook or to the installation video online.

Note: Type, thickness, and format of the tile or stone surface covering must be suitable for the intended application. Minimum tile format is 2" x 2" (5 cm x 5 cm).

Applications with tile formats less than 2” x 2” (5 cm x 5 cm) require special considerations, please contact Schluter-Systems Technical Services Representatives at 800-472-4588 (USA) or 800-667-8746 (Canada) for more information regarding installation requirements and warranty eligibility.

1. Remove release liner from DITRA-HEAT-DUO-PS membrane.

2. Apply peel and stick membrane to the floor, fleece/adhesive side down. Solidly embed the matting into the substrate using a float, screed trowel, or DITRA-ROLLER. Proper installation results in full contact between the adhesive and substrate beneath.

* When using the DITRA-ROLLER, place a weight (e.g., bags of mortar/grout or box of tile) not to exceed 75 lbs on the DITRA-ROLLER shelf. Slowly move the roller from one end of the matting to the other, slightly overlapping successive passes.

3. Abut adjacent sheets and align the studs on the top of the matting to make subsequent heating cable installation easier.

4. The DITRA-HEAT-E-HK heating cables can now be installed. Installation instructions are covered under the DITRA-HEAT-E-HK product page. Note: Tile can be installed directly over the DITRA-HEAT membrane immediately after the DITRA-HEAT-E-HK cables have been installed using an unmodified thin set. Please refer to the Schluter®-DITRA-HEAT Installation Handbook below for complete DITRA-HEAT system instructions.

Alternate Floor Coverings over DITRA-HEAT-DUO-PS

Please refer to detail DH-AFC in the Schluter®-DITRA-HEAT Installation Handbook for complete installation guidelines. Use our DITRA-HEAT calculator to find out what products you need to complete your specific installation.

Warranties

FAQ

Does DITRA-HEAT-DUO-PS provide the same waterproofing properties as DITRA-HEAT-DUO?

DITRA-HEAT-DUO-PS and DITRA-HEAT-DUO feature the same plastic material and configuration.

Read moreCan DITRA-HEAT-DUO-PS be repositioned after the membrane is first embedded to the substrate?

DITRA-HEAT-DUO-PS, depending on substrate and pressure used to initially embed membrane, can be repositioned if needed during installation...

Read moreWhat substrates are strongly recommended to prepare with a suitable primer before installing DITRA-HEAT-DUO-PS?

Typically, wood underlayment subfloors such as plywood or OSB will be the most common applications that would benefit from a primer. Other subfloors to consider are...

Read moreCan I install a tile format smaller than 2”x2” over an uncoupling membrane?

Applications with tile formats less than 2” x 2” (50 mm x 50 mm) require special considerations, please...

Read more

Watch & Learn

About the product

How to install the Schluter®-DITRA-HEAT-PS/-DUO-PS Peel and Stick Membrane

Schluter®-DITRA-HEAT-PS & DITRA-HEAT-DUO-PS Peel & Stick Uncoupling Membranes!

Find some existing tutorials and project documentation videos to learn how-to get the best out of our products - for more fun in your life, start now!

Watch more videos / playlists