Schluter®-KERDI-DRAIN

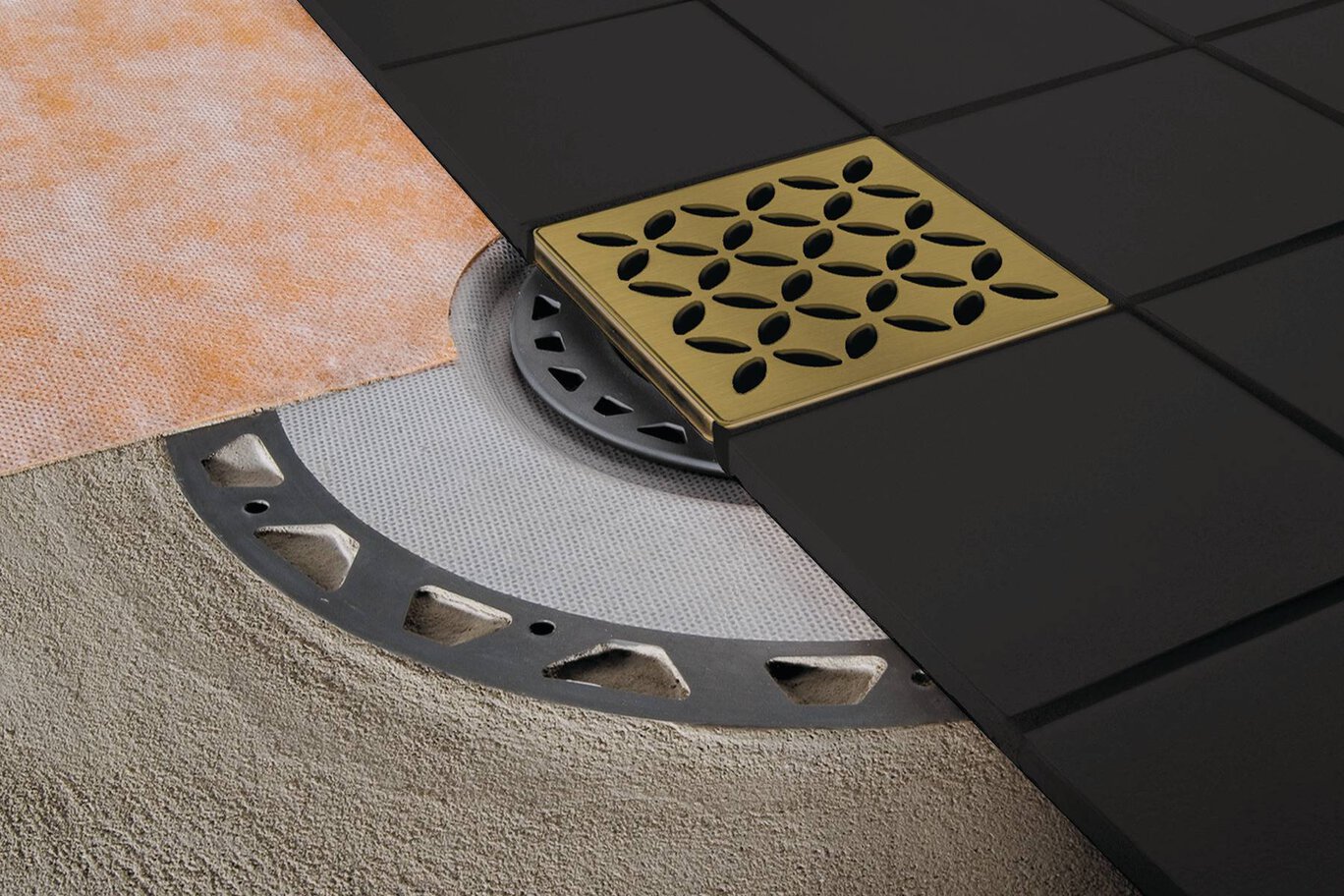

Point drain with integrated bonding flange

- Grate available in a wide range of finishes and colors in stainless steel or anodized aluminum, as well as a tileable option

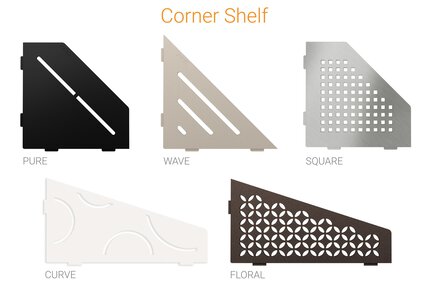

- Available in five stylish designs: FLORAL, CURVE, PURE, CLASSIC, and CONTOUR

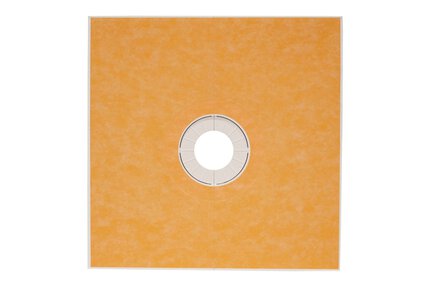

- Integrated sloped bonding flange available in ABS, PVC, or stainless steel allows for a secure, topical waterproofing connection

- ABS and PVC flanges have a 2" or 3" outlet

- Stainless steel flange has a 2" or 3" no-hub outlet or a 2" threaded outlet

- Drain grate can be laterally adjusted to fit the layout of the tile grid and leveled to the tiled surface

- Accommodates wide range of tile thicknesses: 1/4" (6mm) to 1-1/4" (32 mm)

- Tamper proof screws and wrench also available

Find recommended accessories here

Shower System Estimator

Calculate all you need for your shower project.

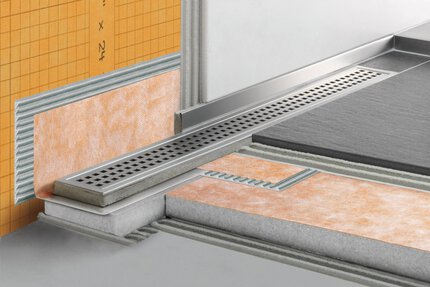

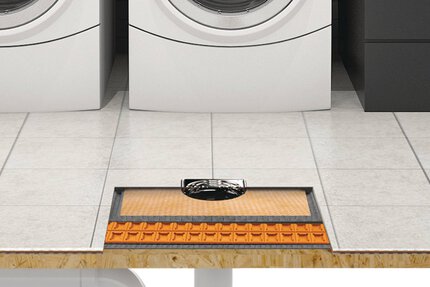

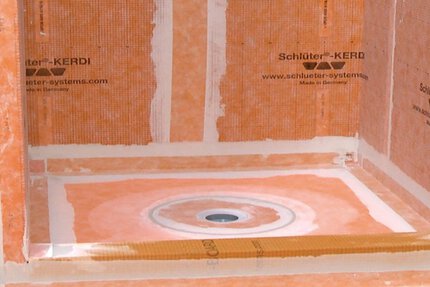

Schluter®-KERDI-DRAIN is a shower drain specifically designed to allow connections to KERDI or other load-bearing, bonded waterproof membranes. The membrane is adhered to the large integrated bonding flange to form a waterproof connection at the top of the drain assembly. KERDI-DRAIN consists of a drain body and fully adjustable grate assembly or covering support to which tile is applied. The grate assembly accommodates a wide range of tile thicknesses and allows lateral and tilt adjustment as well. The covering support is placed flush with the top of the bonding flange and can therefore accommodate any thickness tile covering.

The standard KERDI-DRAIN is attached directly to the waste line. The drain body is available in ABS, PVC, or stainless steel. The plastic drain bodies feature a fleece-covered bonding flange. They are available with standard 2" (50 mm) and 3" (75 mm) outlets and attached to the pipe using an appropriate solvent cement. The stainless steel drain bodies are available with standard 2" (50 mm) or 3" (75 mm) no-hub outlets or 2" (50 mm) threaded outlet. The no-hub outlets are attached to the pipe using an appropriate mechanical (e.g., flexible or no-hub) coupling. The threaded outlets are attached to the pipe using thread sealing compound or tape. The simple connection to standard drain outlets makes KERDI-DRAIN suitable for new construction and renovation.

The KERDI-DRAIN grate assembly consists of a frame, which can be seamlessly adjusted to the thickness and layout of the ceramic tile or stone covering via the height adjustment collar and lateral adjustment ring and grates or cleanout covers that are placed within the frame. The 4" (100 mm) standard grate assembly frame features an approximately 1/8" (3 mm) wide reveal after installation and grate/frame combinations are available in stainless steel in CLASSIC design or anodized aluminum in CONTOUR design, both available in a variety of finishes. The 4" (100 mm) KERDI-DRAIN-STYLE grate assembly frame features a minimal reveal after installation. It is made of brushed stainless steel and can be combined with one of three grate design options: FLORAL (E), CURVE (F), or PURE (G). Various metallic and color-coated finishes are available. The 4" (100 mm) TILE grate is a square stainless steel plate with KERDI laminated on the surface to allow for bonding of ceramic or stone tile, which creates a virtually invisible drainage line. The 6" (150 mm) square and round stainless steel grate assembly frames feature an approximately 3/16" (5 mm) wide reveal after installation and can be combined with stainless steel grates in CLASSIC design or a square cleanout cover. Please note that 6" (150 mm) grate assemblies and grate assemblies used with the 5 -1/4" (133.4 mm) adaptor kits only allow vertical and tilt adjustment (no lateral adjustment).

KERDI-DRAIN requires no special maintenance and is resistant to mold and fungi. The drain grate may be removed to clean the drain housing and the drain pipes.

Clean the grate using a neutral cleaner. Avoid the use of strong acids (e.g., hydrochloric, hydrofluoric) and bases/alkaline cleaners (e.g., bleach, ammonia, chlorides). Do not use abrasive cleaning agents and tools. Even stainless steel requires periodic cleaning, which will maintain a neat appearance and reduce the risk of corrosion. Stainless steel surfaces develop a sheen when treated with a chrome-polishing agent.

The installation instructions below represent the use of Schluter®-KERDI-DRAIN in floor applications. Installation instructions for the use of KERDI-DRAIN in shower applications can be found in the Schluter®-Shower System Installation Handbook.

For a step-by-step guide on installing the Schluter®-KERDI-DRAIN, visit our installation instructions.

Preparation

After locating the correct position, cut a hole in the substrate for the drain outlet and coupling to the waste line using the template provided. Note: Fill in box-outs in concrete floors with dry-pack mortar. A pipe coupling or similar can be used as a form around the waste line. Select form to accommodate the drain outlet and mechanical no-hub coupling (when applicable). Limit the diameter of the hole to 5" (125 mm) maximum to ensure proper support of the tile assembly. A larger hole can lead to lack of support and damage the tile assembly (e.g., cracked grout around drain).

Drain installation

Access to plumbing from below

If there is access to the plumbing from below and the waste line can be connected after installing KERDI-DRAIN, the drain can be installed in conjunction with the mortar bed.

1. Place a ring of loose mortar up to the inlet hole in the floor and firmly press the drain into the mortar. The bonding flange must be fully supported to prevent damage to the tile assembly (e.g., cracked grout around drain). When installing KERDI-DRAIN over wood substrates, the minimum thickness of mortar required at the perimeter of the bonding flange is 1" (25 mm)

2. The screed is then placed flush with the top of the bonding flange of the KERDI-DRAIN. Slope the mortar bed using the bonding flange and mortar screeds as guides.

No access to plumbing from below

When there is no access to the plumbing from below, install the KERDI-DRAIN to the appropriate height prior to the installation of the shower base.

1. Begin the drain installation by dry fitting the components. Measure and cut a section of pipe to connect the KERDI-DRAIN to the odor trap below the floor, using the foam spacers included with the drain as a spacer. When installing KERDI-DRAIN over wood subs trates, the minimum thickness of mortar required at the perimeter of the bonding flange is 1" (25 mm).

2. Prepare the odor trap, cut section of pipe, and KERDI-DRAIN with cleaner, primer and ABS or PVC cement per the solvent cement manufacturer's instructions and connect. Use a no-hub coupling for stainless steel drains with no-hub outlets, and thread sealing compound or tape for stainless steel drains with threaded outlets.

3. Pack loose mortar under the drain up to the inlet hole to ensure solid and uniform support of the bonding flange. The screed is then placed flush with the top of the bonding flange of the KERDI-DRAIN. Slope the mortar bed using the bonding flange and mortar screeds as guides.

Connection to waterproofing membranes

The KERDI or DITRA waterproofing membranes can be installed over the mortar bed as soon as it can be walked upon.

KERDI

1. Apply Schluter SET®, Schluter ALL-SET®, Schluter FAST-SET®, or unmodified thin-set mortar to the bonding flange and surrounding mortar bed with a 1/4" x 3/16" (6 x 5 mm) V-notched trowel or the KERDI-TROWEL, which features a 1/8" x 1/8" (3 x 3 mm) square-notched design. The thin-set mortar must be mixed to a fairly fluid consistency, but still able to hold a notch.

Note: When using the stainless steel bonding flange, the membrane is bonded to the integrated bonding flange with KERDI-FIX adhesive/ sealant. The stainless steel bonding flange must be clean and free of grease or other contaminants prior to KERDI-FIX application.

2. Embed KERDI in the bond coat and work the membrane onto the KERDI-DRAIN bonding flange and mortar bed with the flat side of the trowel to ensure full coverage and remove air pockets. The membrane is carried to the step in the bonding flange (template provided).

DITRA or DITRA-XL

1. DITRA or DITRA-XL is installed up to the outer edge of the KERDI-DRAIN bonding flange. Apply Schluter SET®, Schluter ALL-SET®, Schluter FAST-SET®, or unmodified thin-set mortar to the mortar bed surrounding KERDI-DRAIN with a 1/4" x 3/16" (6 x 5 mm) V-notched trowel or the DITRA-TROWEL, which features an 11/64" x 11/64" (4.5 x 4.5 mm) square-notched design. The thin-set mortar must be mixed to a fairly fluid consistency, but still able to hold a notch. Solidly embed the matting into the bond coat using a float, screed trowel, or DITRA-ROLLER.

2. DITRA or DITRA-XL is sealed to the KERDI-DRAIN bonding flange using a cut section of the KERDI membrane. Apply Schluter SET®, Schluter ALL-SET®, Schluter FAST-SET®, or unmodified thin-set mortar to the bonding flange and surrounding membrane with a 1/4" x 3/16" (6 x 5 mm) V-notched trowel or the KERDI-TROWEL, which features a 1/8" x 1/8" (3 x 3 mm) square-notched design.

Note: When using the stainless steel bonding flange, the KERDI is bonded to the integrated bonding flange with KERDI-FIX adhesive/sealant. The stainless steel bonding flange must be clean and free of grease or other contaminants prior to KERDI-FIX application.

3. Embed a 20" x 20" (50 x 50 cm) cut section of KERDI in the bond coat and work the membrane onto the KERDI-DRAIN bonding flange and surrounding membrane to ensure full coverage and remove air pockets. The KERDI is carried to the step in the bonding flange (template provided) and must overlap the DITRA or DITRA-XL membrane by a minimum of 2" (50 mm).

Grate assembly

Grate

1. The grate assembly is installed in conjunction with the tile. Place the height adjustment collar inside the lateral adjustment ring and snap the grate frame into place.

Note: For drains with 6" (150 mm) grates, the height adjustment collar is integrated with the grate. For the residential adaptor kit, there is no lateral adjustment ring.

2. Fill the step in the bonding flange with Schluter SET®, Schluter ALL-SET®, Schluter FAST-SET®, or unmodified thin-set mortar and back-butter the underside of the grate frame to ensure ful

l support. Press the assembly into the mortar and install the surrounding tiles, ensuring full coverage.

3. Position the grate to match the joint pattern of the tile covering and press flush with the tile surface. Remove all excess setting material.

Note: Protect the visible surface of the grate from contact with setting and grouting materials. In particular, anodized aluminum is sensitive to alkaline materials.

Tileable Covering Support

1. The covering support is installed in conjunction with the tile. Place the tile spacer inside the lateral adjustment ring.

2. Fill the step in the bonding flange with thin-set mortar and press the assembly into the mortar. Install the surrounding tiles up to the tile spacer using Schluter SET®, Schluter ALL-SET®, Schluter FAST-SET®, or unmodified thin-set mortar, ensuring full coverage. Set the tile to the integrated tabs on the lateral adjustment ring, which provide for a flush transition to the covering support. Remove all excess setting material. Position the tile spacer to match the joint pattern of the tile covering.

3. Apply tile to the top of the covering support using Schluter SET®, Schluter ALL-SET®, Schluter FAST-SET®, or unmodified thin-set mortar. The tile is installed flush with all sides of the covering support to provide the drainage openings.

4. Once the assembly has been set and grouted, remove the tile spacer and insert the tiled covering support in the lateral adjustment ring.

Note: For acid-resistant coverings, use an epoxy adhesive to set and grout the tile.

For a step-by-step guide on installing the Schluter®-KERDI-DRAIN, visit our installation instructions.

Data sheets

FAQ

Can I connect an ABS Schluter®-KERDI-DRAIN bonding flange to my PVC waste line, or vice versa?

No, connecting the different plastics violates plumbing codes. ABS must be connected to ABS and PVC must be connected...

Read moreCan I use another manufacturer’s drain with your Schluter®-Shower System?

The Schluter®-KERDI-DRAIN, Schluter®-KERDI-LINE, Schluter®-KERDI-LINE-VARIO drains are specifically designed to integrate with the Schluter®-Shower System...

Read moreWhy should I use the Schluter®-Shower System?

The Schluter®-Shower System is an integrated family of products that together form a fully bonded, watertight assembly for tiled showers...

Read moreWhat is a water test? How do I perform one on the Schluter®-Shower System?

A water test is a quality control check performed on any shower installation before setting tile. It consists of stopping...

Read moreI purchased a standard Schluter®-KERDI-DRAIN bonding flange with a 2 inch outlet; I now need the adaptor ring for an existing clamping ring drain. Will I be able to use this KERDI-DRAIN flange with the adaptor ring?

No, the KERDI-DRAIN bonding flange is not compatible with the KERDI-DRAIN adaptor ring. You will need to use a KERDI-DRAIN...

Read moreCan the KERDI-DRAIN-STYLE and KERDI-LINE-STYLE grates fit into the original KERDI-DRAIN and KERDI-LINE frames?

No they cannot.

CAD drawings

Product Evaluations and Listings

Schluter®-KERDI was evaluated by ICC-ES - ESR-2467

Schluter®-DITRA was evaluated by ICC-ES - ESR-2467

Schluter®-KERDI is listed by cUPC®

Schluter®-DITRA is listed by cUPC®

Schluter®-KERDI-DRAIN is listed by UPC®

Schluter®-KERDI-DRAIN is listed by CSA®

Schluter®-KERDI-LINE is listed by CSA®

Schluter®-KERDI is listed by ICC-ES - PMG-1204

Schluter®-KERDI-DS is listed by ICC-ES - PMG-1204

Schluter®-KERDI-DRAIN is listed by ICC-ES - PMG-1204

System Approvals

State of Kentucky

State of Massachusetts

Watch & Learn

About the product

How to waterproof your shower installation with the Schluter®-KERDI-SHOWER-KIT Complete Kit

Schluter®-KERDI-DRAIN Installation with No Access to Plumbing

How to install the Schluter®-KERDI-DRAIN with a Mortar Base and Waterproofing

How to Install the Schluter®-KERDI-DRAIN Tile Grate

How to perform a Water Test with the Schluter®-Shower System

How to Water Test a Curbless Shower

Find some existing tutorials and project documentation videos to learn how-to get the best out of our products - for more fun in your life, start now!

Watch more videos / playlists