Schluter®-RENO-TK

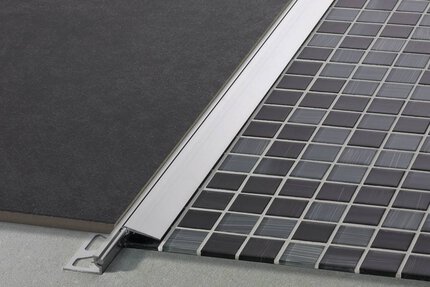

Edge-protection profile with minimum reveal for sloped transitions

- Prevents tile edges from chipping

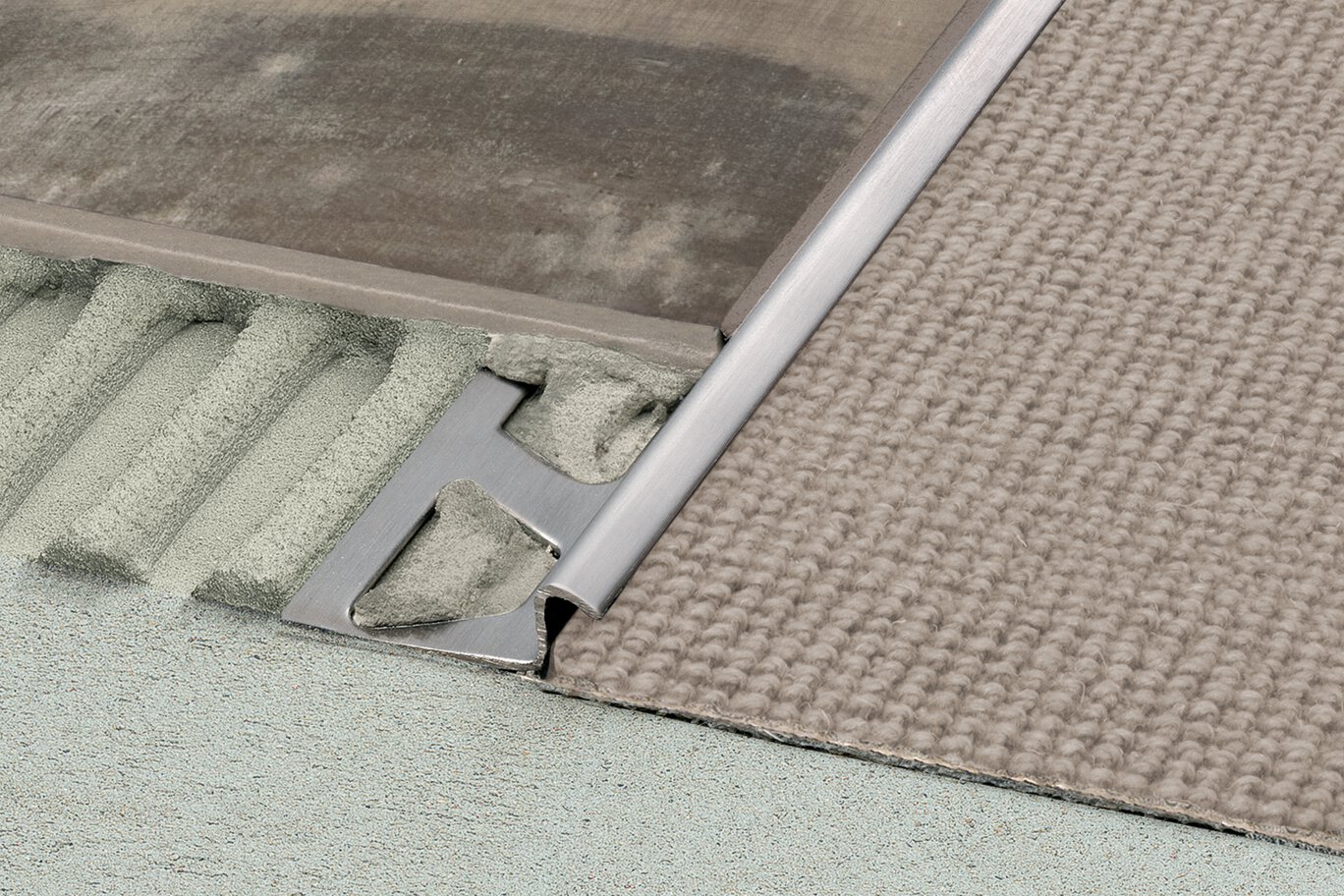

- Typically used to create transitions between tile coverings and carpet at lower elevations

- The 1/4" (6 mm)-wide channel beneath the sloped flange protects and hides the carpet edge

- ADA-compliant

- In certain models, the anchoring leg is available with a radius perforation so that the profile can be used to form curves

Encuentre aquí los accesorios recomendados

Profile Estimator

Discover what you need for tile protection and easy transitions.

Schluter® RENO-TK está diseñado para ofrecer una transición fluida entre el revestimiento de baldosas y revestimientos a menor altura, comúnmente alfombra.

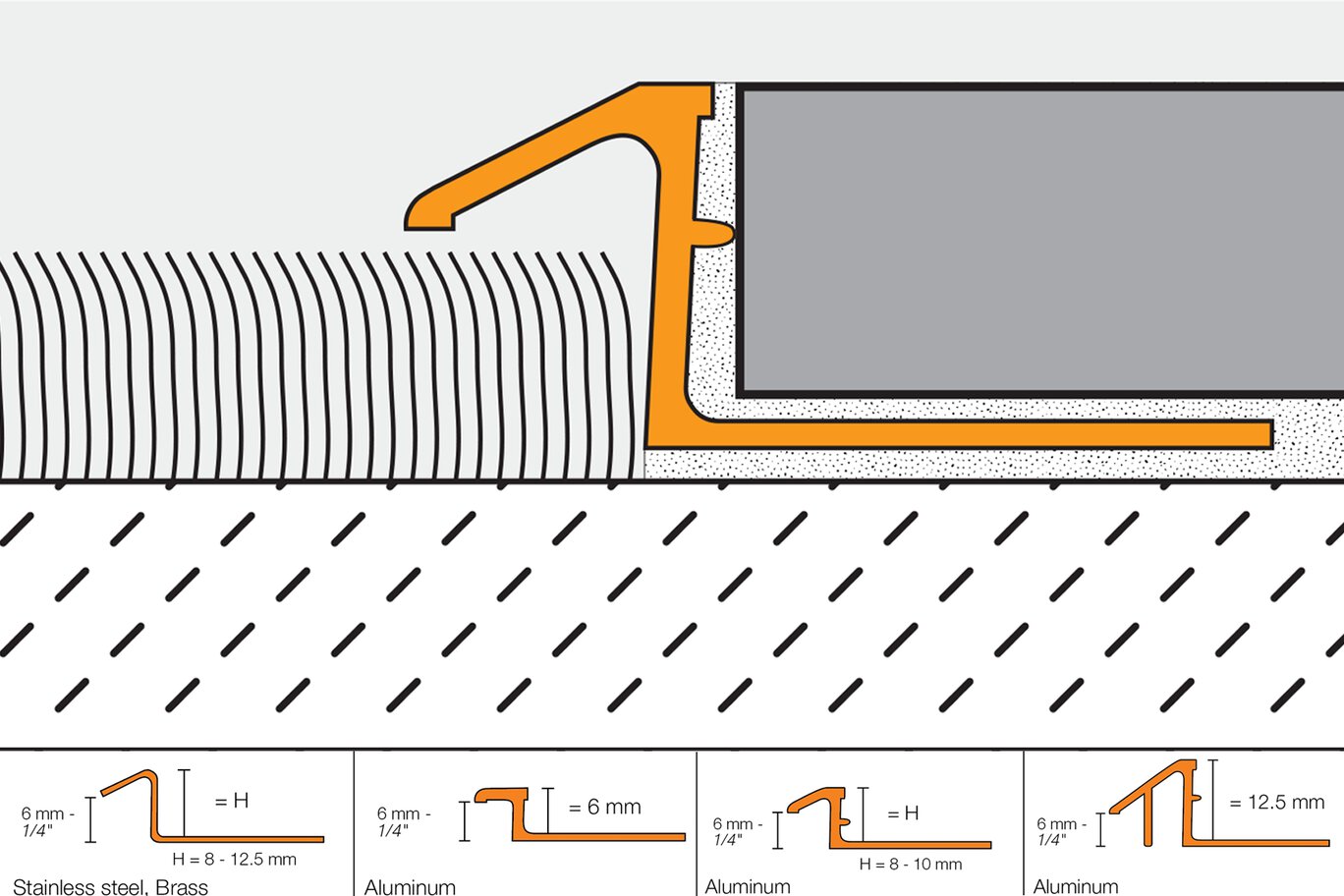

El perfil está disponible en acero inoxidable, latón macizo y aluminio anodizado. RENO-TK Dispone de un ala de fijación perforada en forma trapezoidal que se fija en la capa de adherencia de mortero bajo la baldosa, y una superficie inclinada para evitar tropiezos y caídas y proteger los bordes. El canal de 1/4"(6 mm) debajo del borde inclinado del perfil esconde y protege el borde cortado de los revestimientos adyacentes de menor altura. Todos los tamaños de RENO-TK cumplen con los requisitos de ADA (Americans with Disabilities Act).

RENO-TK en aluminio anodizado dispone de un espaciador de junta integrado que establece una cavidad de junta definida entre la baldosa y el perfil.

El ala de fijación de RENO-TK, en latón macizo y aluminio anodizado, tamaño de 60 a 100, está disponible con un radio especial de perforación "R" que permite que el perfil sea utilizado para formar curvas.

The Schluter®-RENO-TK profile requires no special maintenance or care and is resistant to mold and fungi. Clean profiles periodically using neutral cleaning agents. Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a neutral cleaner. Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. Avoid the use of strong acids (e.g. hydrochloric or hydrofluoric) and base/alkaline cleaners (e.g. bleach, ammonia, chlorides). Do not use abrasive cleaning agents and tools. Stainless steel surfaces develop a sheen when treated with a chrome-polishing agent. Oxidation films on exposed solid brass or aluminum may be removed with a common polishing agent but will form again. In the case of anodized aluminum, do not use abrasive cleaning agents.

1. Select the profile according to tile thickness and format.

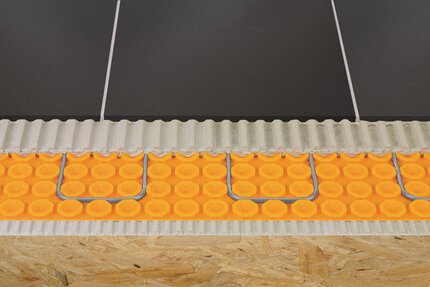

2. Using a notched trowel, apply thin-set mortar to the area where the profile is to be placed.

3. Press the perforated anchoring leg of the profile into the mortar and align.

4. Trowel additional thin-set mortar over the perforated anchoring leg to ensure full coverage and support of the tile edges.

5. Solidly embed the tiles so that the tiled surface is flush with the top of the profile; the profile should not be higher than the tiled surface, but rather up to approx. 1/32" (1 mm) lower.

6. Set the tile to the integrated joint spacer, which ensures a uniform joint of 1/16" - 1/8" (1.5 - 3 mm). With the stainless steel profiles, leave a space of approximately 1/16" - 1/8" (1.5 - 3 mm).

7. Fill the joint completely with grout or setting material.

8. Remove grout or mortar residue from the visible surface of the profile.

FAQ

How do I cut profiles?

Schluter™ profiles are available in a variety of different materials , so methods for cutting vary. Below are best practices for cutting according...

Leer másOnce my tile is installed, it will be higher than the adjacent carpet. What profile would you recommend for this uneven transition?

The Schluter®-RENO-TK profile provides a sloped transition between the tile and carpet and features a channel below...

Leer másDibujos CAD

Ver y aprender

Acerca del producto

How to install a tile transition on floors: Schluter®-RENO-TK profile

Introduction to Schluter® Profiles

Tips on How to Choose Your Profile Size in Relation to Your Tile

Tips on Cutting Profiles

How to Flatten your Substrate for Schluter® Profiles

Encuentre tutoriales y videos de documentación de proyectos para aprender cómo sacar mejor provecho de nuestros productos, ¡empiece ahora y diviértase!

Ver más vídeos / listas de reproducción